March 2025

Engineering Tips: Standard Deflections

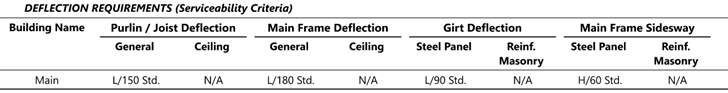

The Deflection Requirements or Serviceability Criteria section of the sales order may seem like a small part of the scope, but it can have a huge impact on your project. In this Tips from Engineering we discuss the standard deflections and how correctly defining the criteria can result in the most cost effective project.

Deflection requirements define the maximum deflection or movement a member is to be designed for. They are given as “L” for length or “H” for height, both in inches, over a number.

As an example, let’s look at the standard L/150 purlin deflection for a 30ft bay. If we have a 30ft long purlin, the maximum allowable deflection is 30ft/150 = 2.4 inches. If we have a higher deflection criterion, such as L/360, the individual purlins must hold a max of 1 inch for the same length.

Let’s dive into each of the standard deflections seen above. The purlin deflection is the vertical deformation that occurs in-between main frame rafters. Similarly, the main frame deflection is representative of the vertical deflection in the frames themselves. It should be noted that if a hanging ceiling is present, the standard deflection would become L/240. To meet this stricter deflection limitation, engineers may use additional purlin runs, heavier gage purlins, nested purlins, deeper frame rafters, or other frame reinforcement as needed.

Next are the horizontal deflections. Like Purlins, Girt Deflection refers to the horizontal distance the girts deflect in-between main frame columns. Main Frame Sidesway is also measured in a horizontal distance, but it is applied to the horizontal deflection of the frame itself (parallel to frame) and the horizontal deflection of the frame allowed by the bracing system (perpendicular to the frame). Reinforced masonry walls are a common condition that requires a stricter deflection criterion in these sections. The standard L/240 Girt Deflection is used for typical masonry conditions with a H/100 Main Frame Sidesway, which is much stiffer and does not bend the same as our girts. This raised deflection limitation is necessary because too much deflection in these systems can cause masonry walls to crack. Common ways engineers meet these deflection limitations are with heavier gage girts, nested girts, spandrel beams, deeper frame columns, heavier rod or angle bracing, additional bays of bracing, reinforced portal frames, or other frame reinforcement as needed.

Deflection in your building is not a bad thing and in general, pre-engineered buildings are designed to deflect more than other types of construction. It’s important to know that when a stricter deflection criteria is required on a project, the structure supporting it will usually require heavier framing, reinforcement, or additional design considerations. Defining the deflection criteria you need in the right category helps your engineer provide the best and most economical solutions for your project.